[Blog] GS1 – Power of standardization and the benefits of efficient data exchange

Global standards such as GS1 are essential for the efficiency of healthcare systems. They are important for improving patient safety and well-being. The power of standardization and the benefits of efficient data exchange is doubtless.

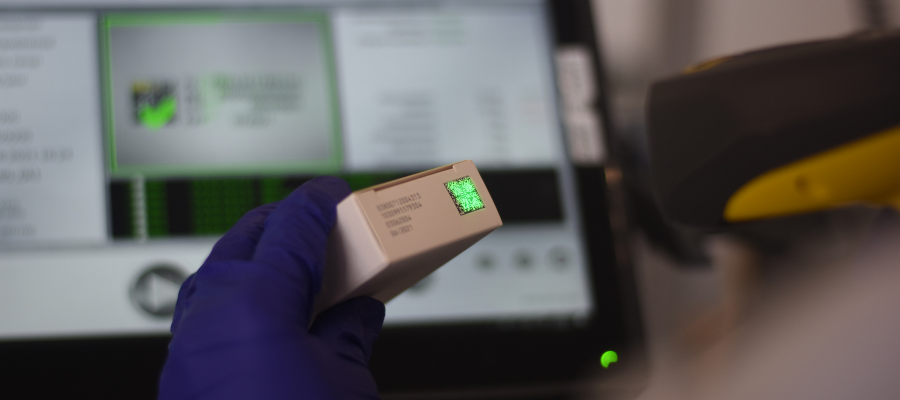

The fundamental concept driving GS1 standards is to facilitate transparency within the supply chain. GS1 Barcodes enable the encoding of information (key identifiers and attributes) and allow the Track and Trace through the whole supply chain.

This is the first article from the upcoming series about GS1 global standards. We are about to give you valuable insights about some of the defined ID keys, as well as the crucial benefits and impact of global standardization on the healthcare worldwide.

We will take a closer look at GS1 identification keys, such as:

- Global Trade Item Number (GTIN)

- Global Location Number (GLN)

- Serial Shipping Container Code (SSCC)

Table of Contents

The power of GS1 standards

Nowadays, companies are becoming more willing to adopt new processes and systems to make the best use of global standards. Certain pharmaceutical and medical device manufacturers are now using global standards such as GS1 Global Trade Item Number (GTIN), GS1 Global Location Number (GLN), and data exchanges such as the GS1 Global Data Synchronization Network (GDSN).

These standards guarantee compliance with regulations in the pharma industry.

Regulators around the world are defining new supply chain requirements to protect patients from substandard and defective products and ever more sophisticated counterfeits, especially pharmaceuticals, although medical devices are also raising concerns.

Pharmaceutical manufacturers are being required to serialize products with unique identifiers at the unit of sale level, which often requires new capabilities and large investments in hardware and software.

Why serialization is important?

When products are serialized, the standardized product identification can be captured automatically as the product moves through the supply chain, down to the point of use, which has many additional benefits. The barcode can be applied to secondary or primary product packaging, as well as higher packaging levels (cartons or pallets when talking to aggregation), and certain barcodes allow multiple data elements to be captured, such as GS1 DataMatrix.

Serialization at the primary package level

Serialization may help prevent medication errors in hospitals and improve supply chain efficiency by increasing the visibility of true product usage.

Serialization at the secondary package level

Some pharmaceutical products already carry this serialization to help providers authenticate the product. Some manufacturers have implemented serialization systems voluntarily, aiming to reduce the counterfeiting of specific products in their portfolio, as a preparation for systems that would authenticate their products at the dispensing points.

Each level of packaging could be identified by a barcode. Barcode scanning when medications or medical devices are used can offer detailed, real-time insights into usage and demand that are valuable to manufacturers, providers and regulators.

Source:

https://www.gs1.org/